Laser Beam Analyzer LBA_023

Laser beam analyzer LBA_023 are used to determine the quality of a laser beam. Laser beam analyzers measure beam profile, average power, energy per pulse, frequency, and temporal pulse shape.

LBA_023 provides vital information on the quality of laser beam light. Laser quality is important for maintaining the precision of laser cutting and welding processes. A laser beam analyzer can be used as a diagnostic tool, monitoring the various laser beam parameters. LBA_023 comes with data storage and analysis software.

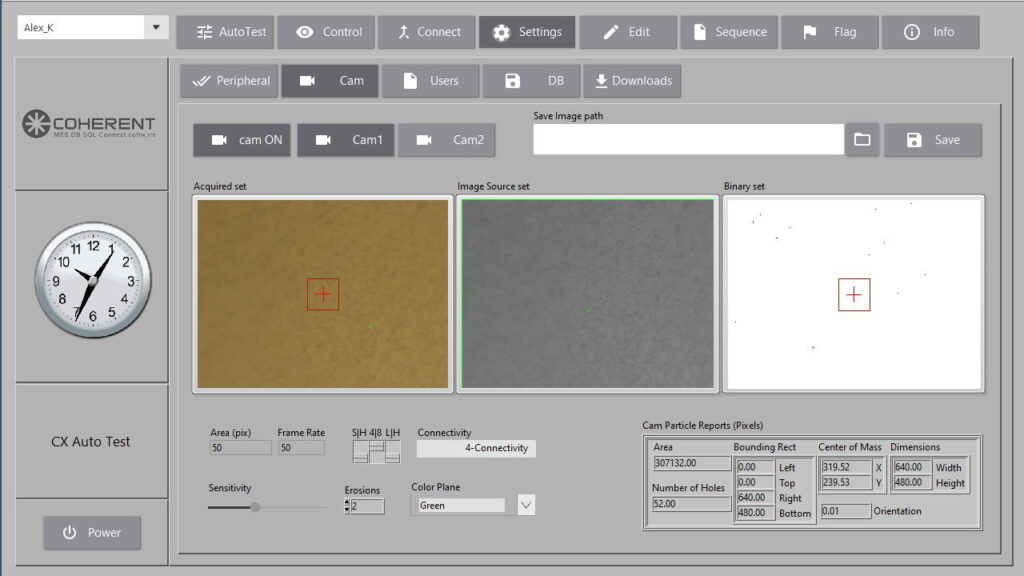

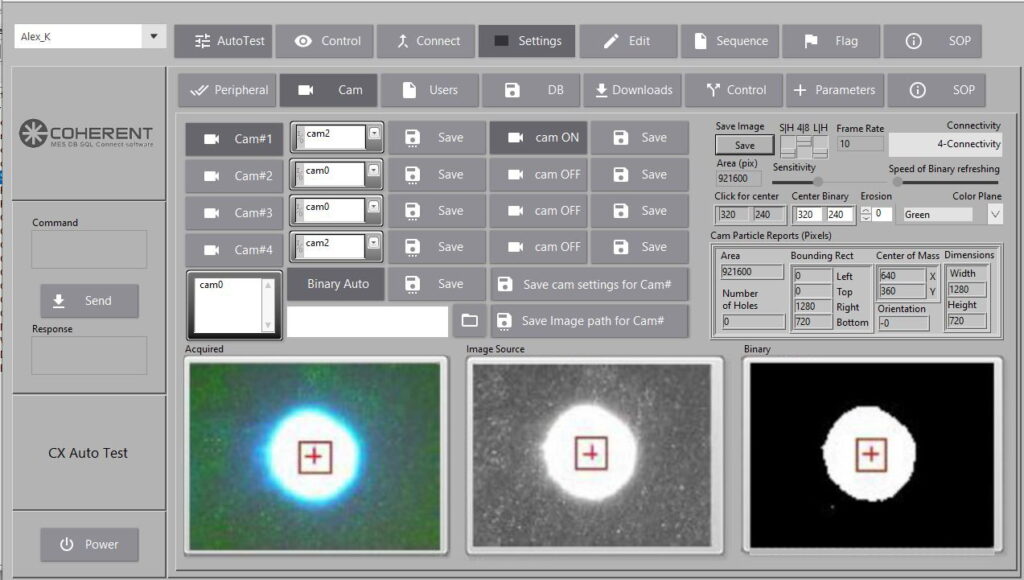

LBA_023 monitors and measures a laser beam quality parameter known as M squared. M squared is an International Standards Organization (ISO) standard used to describe how close a laser beam is to a perfect Gaussian measurement and how well the laser beam can be focused as its target. LBA_023 can capture small differences in laser beam delivery due to varying tolerance ranges in lenses, mirrors, and other components, as well as any environmental conditions that may be affecting the laser beam. LBA_023 come with analog or digital camera systems and software for analyzing the images.

LBA_023 includes optical spectrum analyzers, which are used to examine the optical spectrum of a laser.

LBA_023 has an optical spectrum analyzer that consists of a passive filter with a pair of mirrors at opposite ends of a cavity. The mirrors are separated by a piezoelectric cylinder. Voltage applied to the cylinder causes the cylinder to lengthen, shifting the transmission peaks of the analyzer allowing it to resolve the narrow spikes in the laser’s output.

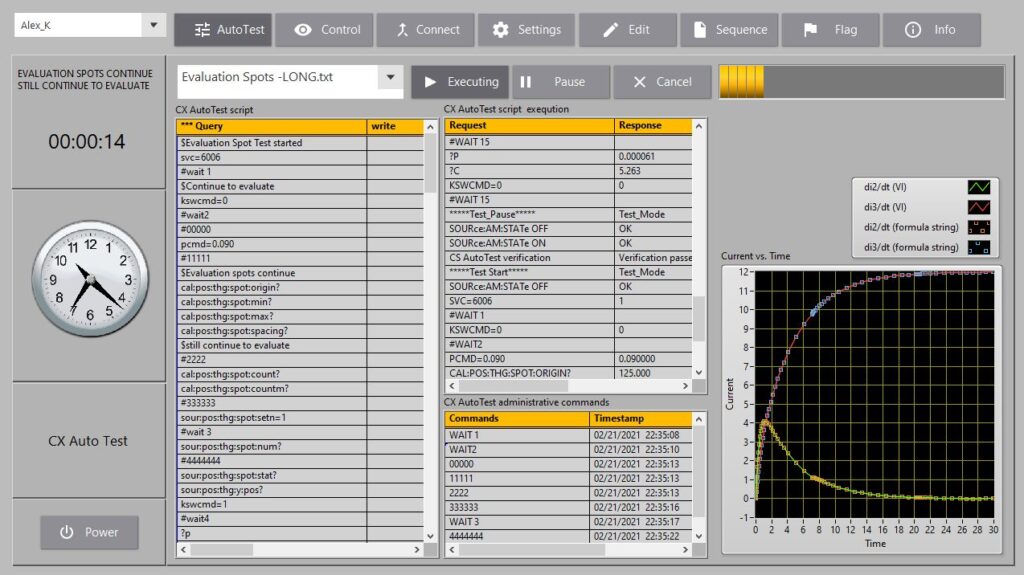

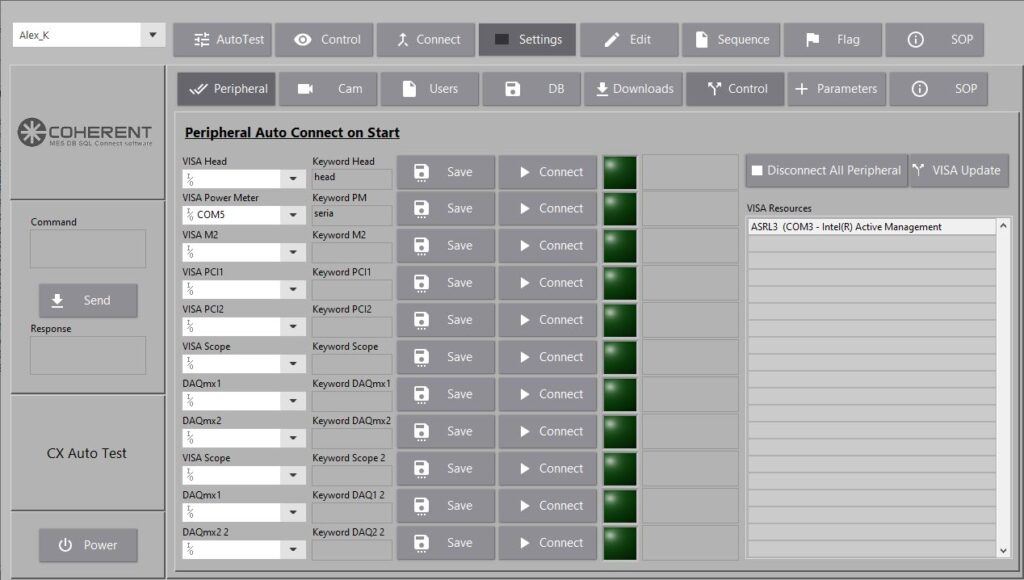

The characterization is made by using high end measurement devices:

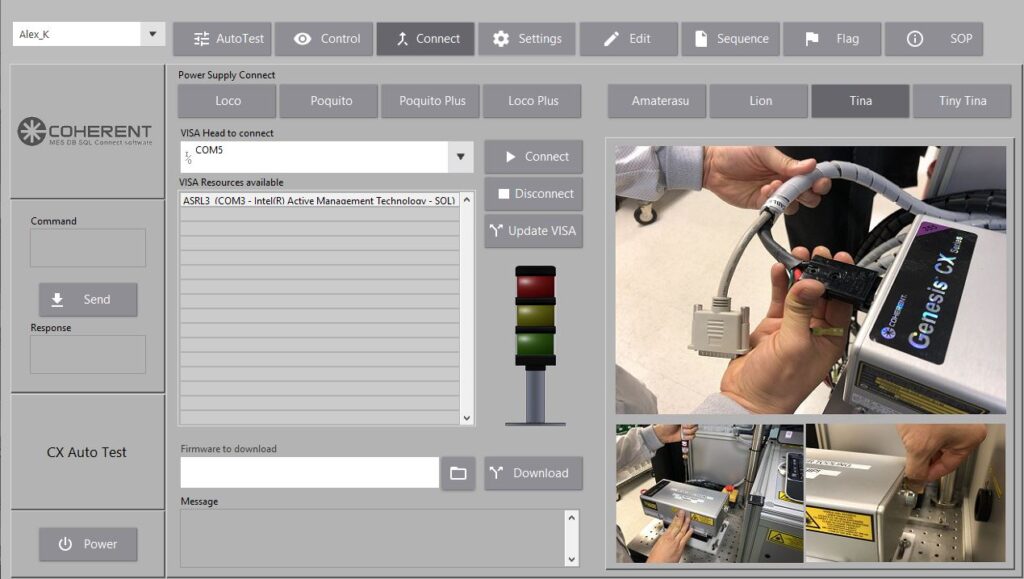

Multiple Laser’s systems are embedded to the GUI setup.

Characterization of the system using LeCroy before employment to the production plan.