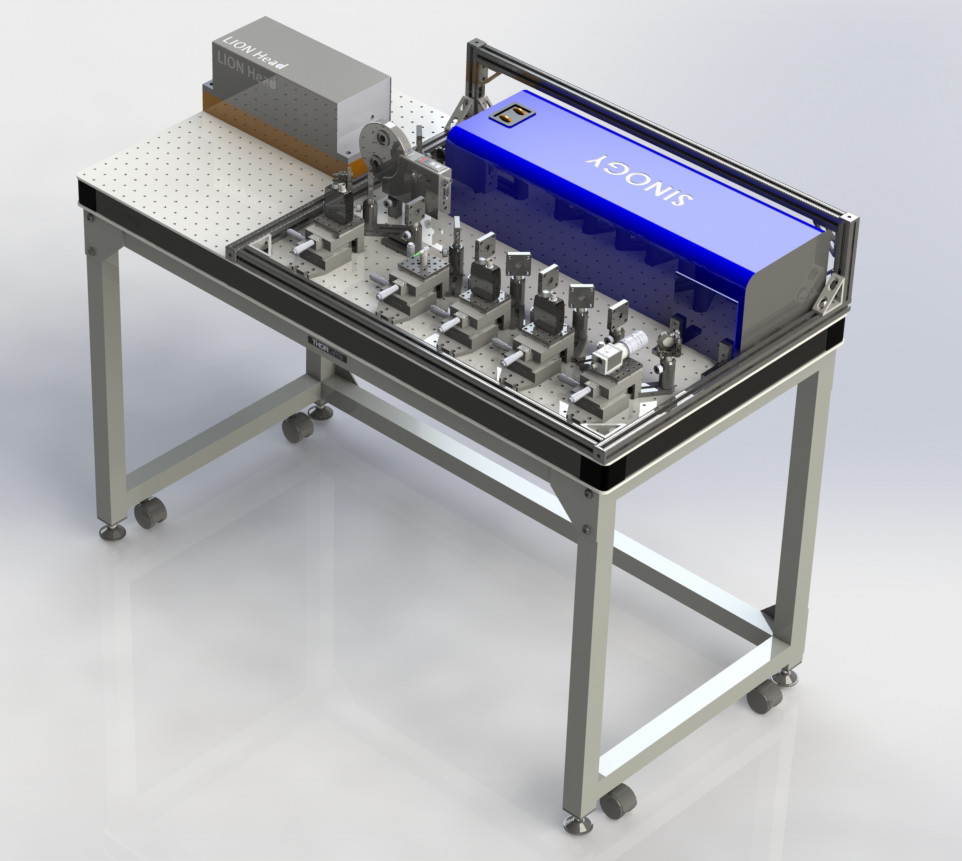

SX-Auto Test Station

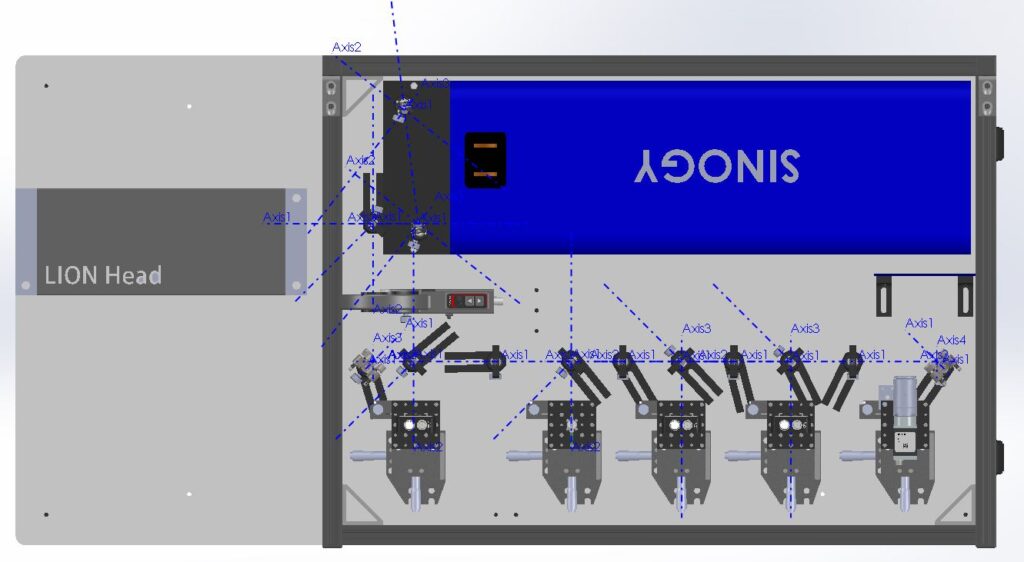

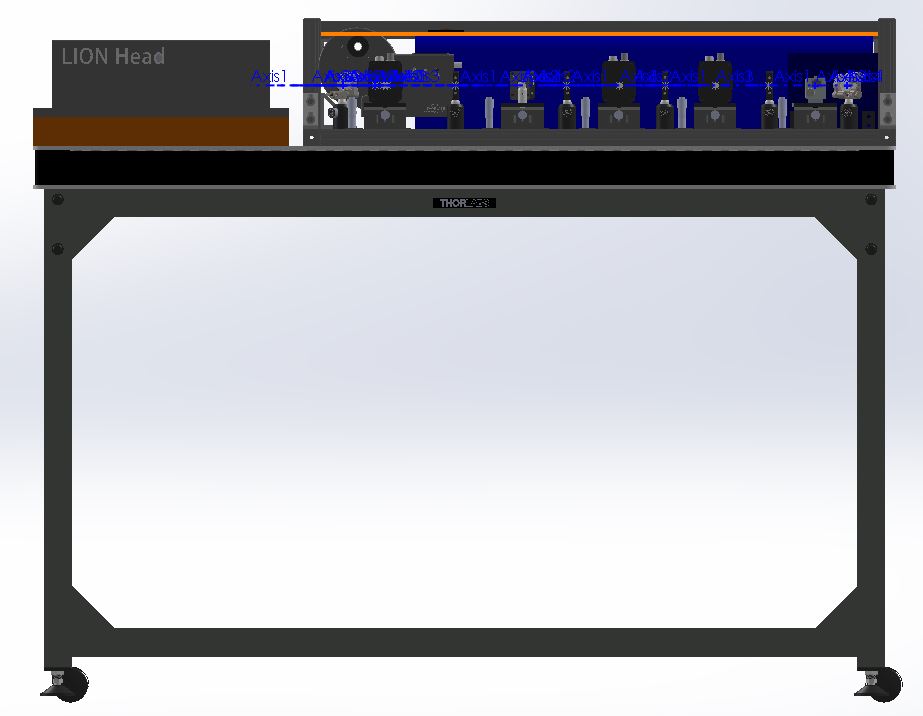

CX-LS036 is intended to be the device for the laser beam M2 factor characterization, also called beam quality factor or beam propagation factor for measure of the beam quality of a laser beam. According to ISO Standard 11146 [6], it is defined as the beam parameter product divided by, the latter being the beam parameter product for a diffraction-limited Gaussian beam with the same wavelength. The device is also designed for multiple measurements for to complete the specification.

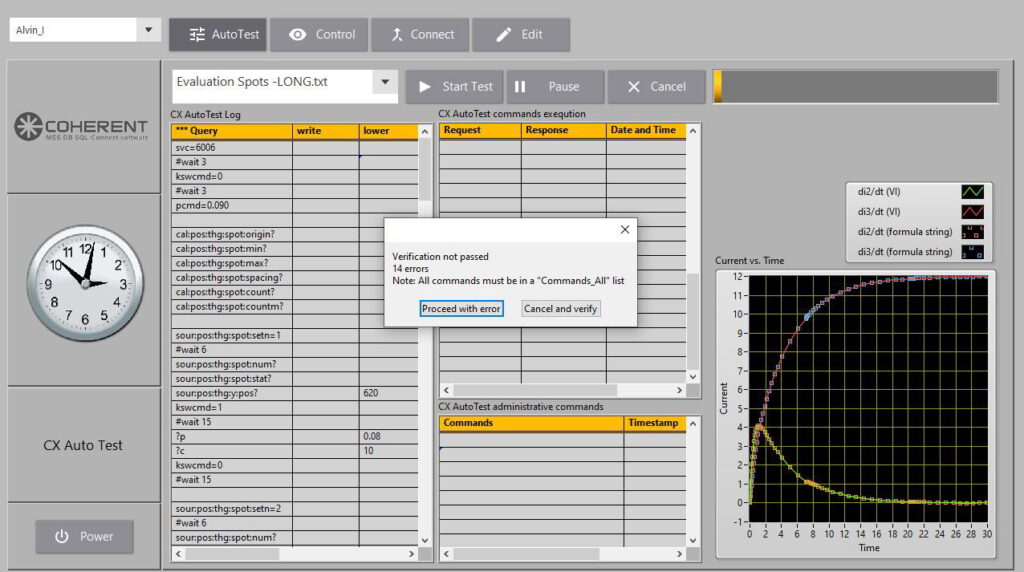

CX-LS036 control is performing by the advanced GUI.

Some frequently made mistakes in measurements are fixed and excluded from the technique: ⦁ The beam radius is measured with a simple criterion, not based on the full intensity profile, although the beam profiles are not all close to Gaussian. Only for nearly Gaussian beam shapes, such simple measurement methods are allowed. For others, the D4σ method based on the second moment of the intensity distribution must be used.

⦁ The beam is focused too tightly, so that the beam waist is too small to measure its beam radius precisely. For example, a CCD camera has a limited spatial resolution; it cannot be used for precise measurements if the beam diameter corresponds only to a few pixels.

⦁ Background subtraction, a sensitive issue for the second-moment method, is not correctly done. Camera images can exhibit some background intensity level, which may either really be belonging to the laser beam (and should not be removed then) or is an artifact which must be removed. If such a background results from ambient light, the most reliable measure is to switch this off, or to carefully shield it with a black tube in front of the camera. (Subtracting a fixed level for all images is problematic since ambient light levels may change, e.g. when somebody moves in the room.) The background issue is particularly serious when the beam size is only a fraction of the camera’s sensitive area.

⦁ The beam intensity on a camera is too high or too low. If it is too high, the center pixels may be saturated, so that the beam intensity at the center is underestimated and the measured beam radius is too large. For too low intensities, intensity background issues may become more severe.

⦁ The beam radii are not measured sufficiently far from the focus. In order to properly judge the beam divergence, the ISO 11146 standard demands that about half of the measurement points must be more than two effective Rayleigh lengths away from the beam focus (whereas the other half of the points is close to the focus, i.e., within one Rayleigh length). This may be difficult in practice when the beam waist is made relatively large, leading to a long Rayleigh length and correspondingly large space requirements for a correct measurement.