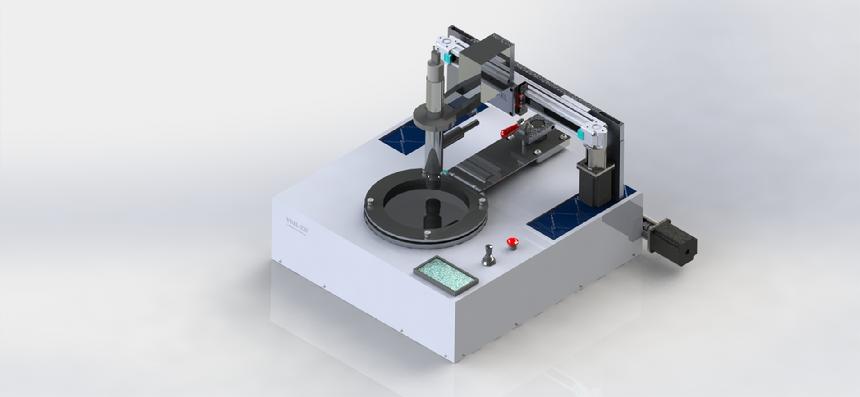

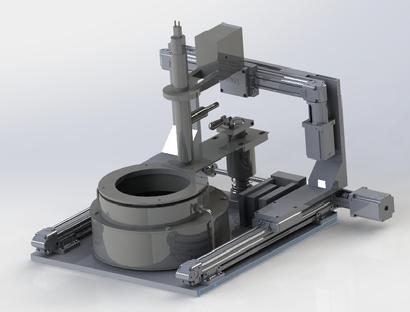

Vertical cavity mirroring station

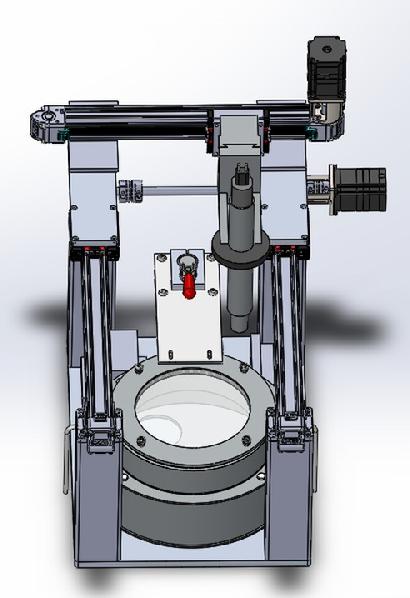

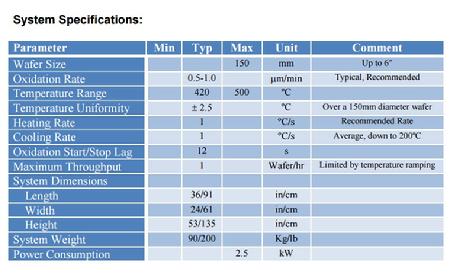

Wet Oxidation System for VCSEL Fabrication is a stand-alone lateral wet oxidation system intended for the fabrication of Vertical Cavity Surface Emitting Lasers. It is an atmosphericpressure oxidation system with in-situ monitoring of oxide aperture formation. It accommodates single wafers of up to 150mm (6″) in diameter

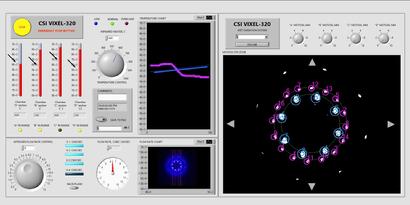

In-situ oxidation monitoring is done by an infrared optical microscope that is focused on VCSELs or oxidation test structures. Typically, the oxidation duration is selected as an upper limit in the software, while the operator monitors the oxidation progress. The process stops either automatically at the maximum duration programmed, or by the operator when the desired aperture size is reached.

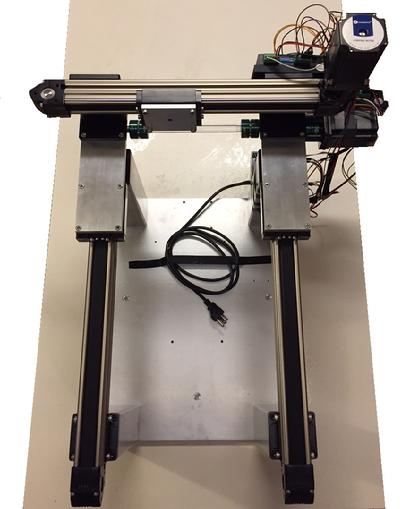

Device is controlled by a provided computer and a software package that allows either manual or programmed operation of the system. Oxidation progress is viewed in a separate window with the capability to optimize the image and to save still images or video clips of the oxidation as needed. The manual tab in the user interface is shown below. Various parameters are chosen and activated by the user. This mode of operation is useful for experimentation and optimization.

The user creates system programs according to the requirements of each product. A program consists of a set of system parameters that change over the course of wafer oxidation. Each program may be recalled and executed as needed, or the system may be operated in manual mode. Maximum allowed chamber temperature is 500ºC. Typical oxidation temperature range is ~ 380-440 ºC.